+91 99000 15883

+91 99000 15883

Jindal Group is the largest manufacturer of ERW pipes well diversified in various piping systems such as PE-AL-PE Pipes (also known as Multi-Layer Composite Pipes or Jindal MLC Pipes), HDPE Pipes, PVC Pipes, UPVC Pipes and CPVC Pipes.

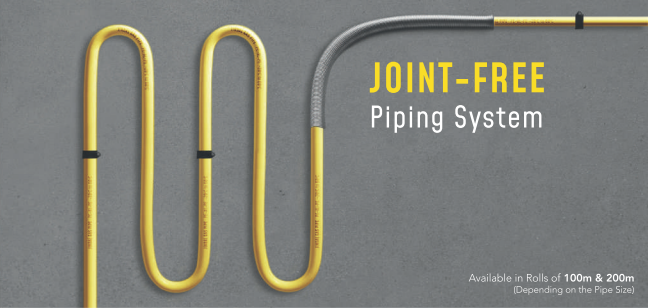

Jindal MLC Gas Piping system combines the advantage of metal and plastic, and eliminates the disadvantages of both materials at the same time. The aluminium core is absolutely diffusion tight and reliably prevents oxygen or gases from permeating. It compensates and reduces snap-back and heat expansion with changes in temperature.

Jindal MLC Gas Pipes and fittings are manufactured with the latest german technology at our state of the art facility in Dehradun, Uttarakhand, India.

Jindal MLC Gas Pipes are an ideal choice for indoor and outdoor installations. The pipes conform to stringent international standards for gas piping systems and multilayer piping technology.

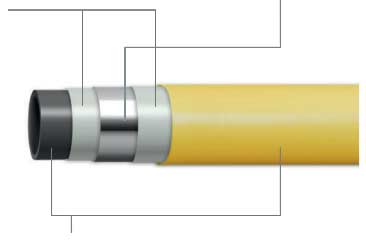

Adhesive Layers

The adhesive layer perfectly bonds the polyehtylene and aluminium layers and absorbs the eventual shifting movements between the layers

Aluminium Core

The aluminium core stays where it lays and has high mechanical strength. It has the ability to withstand high temperatures and pressure.The aluminium core acts as the pipe's backbone with its mechanical resistance to deformation.

Internal & External Polyethylene Layers

The Polyethylene Layers are lightwieght, flexible and chemically inert. It provides a smooth surface for better flow and is a food grade material.

50 Years of Working Life

Hygienic, Toxic Free, Rust Free & No growth of micro-organisms

Easily bendable never spring back

Easy installation and wide range of usage

Light in weight and easy to carry and store

Low expansion and contraction

Quite Flow

Fire Retardant

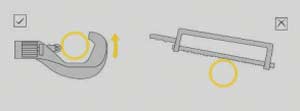

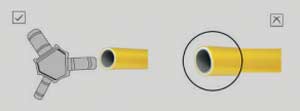

Pipe should not be cutusing hacksaw blade cutter. Only Jindal MLC Pipe Cutter should be used

It is essential to use bending spring for bending of the pipe as it maintains the shape of the pipe.

Pipe Reamer should be used on the pipe before installing the fitting. It expands and makes the pipe round for proper installation of fitting

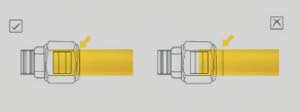

While inserting the fitting into the pipe it should be ensured that the pipe reaches the end wall of the fitting and covers both the 0-Rings.